In recent years, 3D printing has transformed the manufacturing industry, offering innovative solutions to traditional production challenges. This technology has paved the way for unprecedented levels of customization, efficiency, and cost-effectiveness in manufacturing processes. In this article, we’ll delve into the world of 3D printing, exploring its applications, benefits, and profound impact on the manufacturing landscape.

What is 3D Printing?

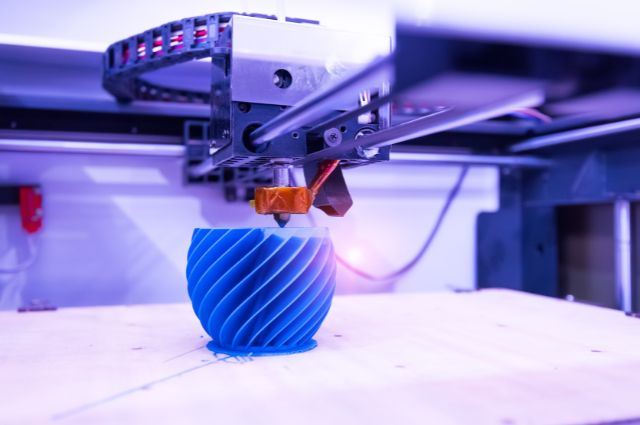

3D printing, also known as additive manufacturing, creates three-dimensional objects by layering successive material deposits based on digital 3D models. Unlike traditional subtractive manufacturing methods that involve cutting away material from a solid block, 3D printing builds objects layer by layer, enabling precise and intricate designs to be realized with unparalleled accuracy.

How Does 3D Printing Work?

The process of 3D printing begins with creating a digital 3D model using computer-aided design (CAD) software. This model serves as a blueprint for the object to be printed, specifying its shape, dimensions, and intricate details. The 3D printer then interprets this digital model and translates it into physical form by depositing successive layers of material, such as plastic, metal, or resin, until the final object is fully realized.

Applications of 3D Printing in Manufacturing

Prototyping

Rapid prototyping of product designs is enabled by 3D printing, allowing manufacturers to iterate and refine concepts swiftly before moving to full-scale production. This acceleration of the product development process reduces time-to-market.

Customization

Manufacturers can easily customize products to meet the unique needs and preferences of individual customers using 3D printing. This level of personalization fosters greater customer engagement and satisfaction.

Tooling and Fixtures

3D printing is increasingly producing customized tooling, jigs, and fixtures for manufacturing processes. These bespoke tools streamline production workflows, improve accuracy, and reduce costs.

Spare Parts Production

On-demand production of spare parts is facilitated by 3D printing, eliminating the need for extensive inventory storage and minimizing downtime in the event of equipment failure. This enhances supply chain resilience and operational efficiency.

Complex Geometries

3D printing excels in creating complex geometric shapes and intricate designs with precision and consistency, unlike traditional manufacturing methods. This capability opens up new possibilities in product design and functionality.

Benefits of 3D Printing in Manufacturing

Cost Savings

3D printing reduces material wastage and labor costs associated with traditional manufacturing processes, leading to significant cost savings for manufacturers.

Time Efficiency

The rapid prototyping capabilities of 3D printing accelerate product development cycles, enabling manufacturers to bring new products to market faster and stay ahead of competitors.

Design Flexibility

3D printing offers unparalleled design freedom, allowing manufacturers to create highly complex and customized parts that would be difficult or impossible to produce using traditional methods.

Sustainability

By minimizing material wastage and energy consumption, 3D printing promotes sustainability in manufacturing, aligning with the growing demand for environmentally friendly practices.

On-Demand Production

Manufacturers can produce goods on-demand, reducing the need for large-scale inventory storage and enabling more responsive supply chains.

Challenges and Considerations

While 3D printing offers numerous benefits, it also presents certain challenges and considerations for manufacturers to address:

Material Limitations

The range of materials suitable for 3D printing is currently limited compared to traditional manufacturing processes, restricting its applicability in certain industries.

Quality Assurance

Ensuring the quality and consistency of 3D-printed parts can be challenging, requiring stringent quality control measures and testing protocols.

Intellectual Property Concerns

The ease of replicating digital designs in 3D printing raises concerns about intellectual property protection and unauthorized copying of proprietary designs.

Regulatory Compliance

Compliance with industry regulations and standards remains a concern in 3D printing, particularly in sectors such as healthcare and aerospace where safety and reliability are paramount.

Future Outlook

Conclusion

In conclusion, 3D printing represents a paradigm shift in manufacturing, offering unprecedented opportunities for customization, efficiency, and innovation. By leveraging the capabilities of 3D printing, manufacturers can streamline production processes, reduce costs, and create products that are tailored to the needs of individual customers. As the technology continues to evolve and mature, its impact on the manufacturing industry will only grow, ushering in a new era of manufacturing excellence and creativity.